This guest post is written by Jason Smith, founder of CowTech.

When I first came across the BQ Ciclop I was thrilled. I had been looking for something to replicate parts on equipment and machinery that had broken on my ranch. It was reasonably affordable compared to much of the competition, and I could 3D print my own parts, so I could feel like I was truly integrated into the production of the machine. However, when I got to thinking about it, I realized that my desktop 3D printer, an entry level RepRap printer, cost just about the same as the scanner, despite having a far more complex design. A scanner is an accessory to a printer, and as such should cost less than the machine it supports. A lot less.

Doing some back of the envelope calculations I realized that I could source the parts for the BQ and sell complete scanners for about half what BQ charged, and it was open source, so I was free and even encouraged to sell it in any way I wanted.

When I saw this was going to be a sizable project, I partnered with my high school friend and 3D printing enthusiast, Weston Downs. Kickstarter campaigns often advertise significant savings over the retail price of the product, 20%, 30%, sometimes even higher discounts. This of course is logical: startup companies are willing to run on much thinner margins to gain sales momentum and keep the lights on, they have lower overhead costs, and the product is selling directly to the consumer instead of going through retail margin hikes. For us, the typical “Kickstarter Discount” wasn’t enough. This was a project where we could truly come in with a disruptive price-point and make 3D scanners affordable enough that everyone who owned a printer could buy one, and it would be a true accessory, one that cost a fraction of the cost of the 3D printer. We set our goal at $100, and got to work.

We changed several parts on the machine to reduce cost, primarily the bearing that supports the turntable and the microcontroller, then designed our own shield to run the scanner. At the end of the day, after meticulously sourcing parts at volume from many different manufacturers and getting samples from each one to ensure quality, we ended up with a set of components that let us reach that lofty, but clearly attainable $100 goal.

We wanted to make sure that the functionality of our scanner was the same as the BQ it was modeled after, so we build a BQ from scratch to check. Once we started printing the parts we noticed another area that we could improve upon dramatically. The BQ took almost 28 hours to print, and filled up most of the bed on our Prusa i3s, which is larger than most printers. What if we redesigned all the parts to take less time, use less filament, require a smaller print volume, and look sleeker?

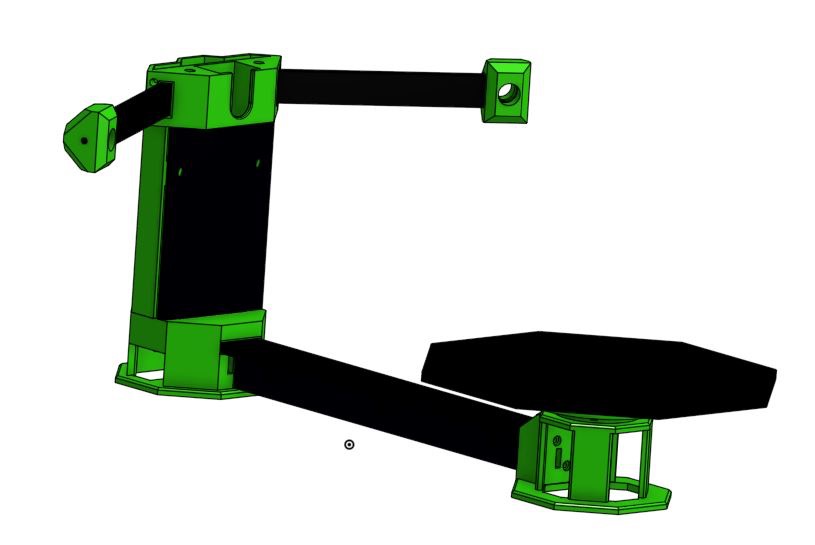

The task of overhauling the design on the entire scanner was daunting, but our engineering intern from Montana State University, Marcus Jolovich, went right to work. In addition to cutting the print time in half, reducing the bed size to 115mm x 110mm x 65mm, and using 33% less filament, we replaced the ugly threaded rod with sleek acrylic that can be custom engraved and easily sliced with precision on our laser cutter. A magnetic back cover to easily access the electronics and an internal LED glow to set it apart aesthetically were also added, resulting in a scanner that kept the same functionality as its parent but sported a far lower price and a sleek new aesthetic redesign.

After months of effort, we are finally live on Kickstarter, and are on track to reach our funding goal in the first 24 hours. We want to see a scanner in the hands of every 3D printing enthusiast in the world. The 3D printing revolution has come, and it’s time for the 3D scanning revolution to follow. That’s why we released the CowTech Ciclop: a RepRap 3D scanner with a large scan volume, simple, yet elegant design, and a disruptive price point that blows any other laser scanner out of the water. The user prints the plastic parts on their own printer in any color and resolution they choose, and can assemble the scanner in less than 30 minutes. Then, simply take any object you want to replicate, set it on the 200mm laser cut acrylic turntable, and start scanning. We wanted to make sure our product was usable for anyone who owns a 3D printer, so we meticulously designed our parts for a print bed volume of only 115mm x 110mm x 65mm (4.5 x 4.3 x 2.6in) so they can be produced on even the smallest of printers.