Chromatic 3D Materials has developed a system for printing ultra-smooth elastomers for use as gaskets and seals.

Their Chromatic RX-AM materials and technology platform comes with Smooth-Mode technology for printing rubber parts is an extrusion-based process utilizing thermoset elastomers. It is ultra-smooth, alleviating the need for post-processing, and is designed to print at industrial quantities.

You can see an example of some printed grommets in the image below.

Founded in 2016, and with locations in the US and Germany, the company offers itsRX-AM platform which is a 3-in-1 solution that includes the materials, software and hardware for deposition printing of elastomers.

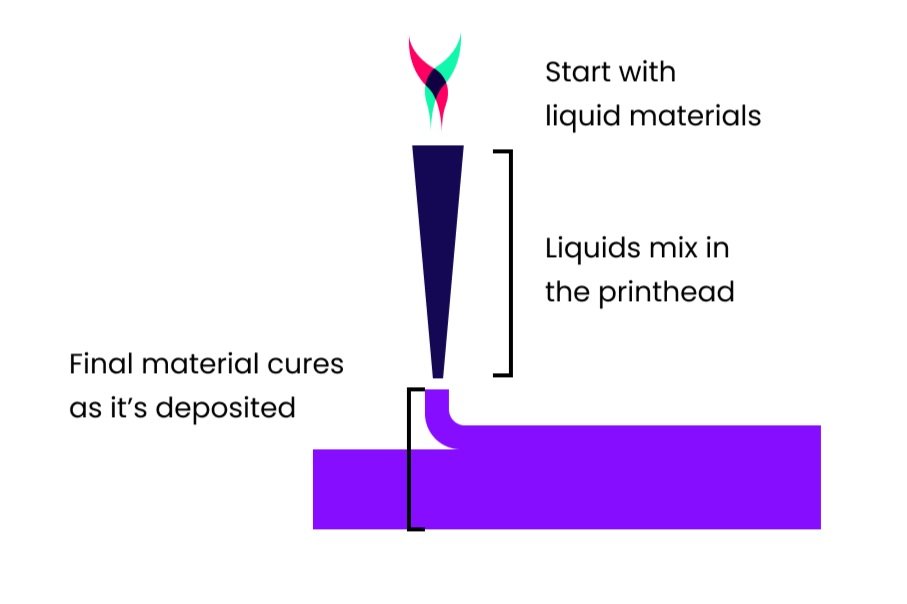

It is based on Reactive Extrusion Additive Manufacturing, a type of thermoset polymer 3D printing that uses chemical reactions rather than variations of heat to cure the plastic into its solid form.

The system is capable of producing high-quality polyurethane parts, such as seals, gaskets, grommets, bladders and other elastomeric products, with no need for post processing or surface finishing.

“Sealing requires a smooth surface, but 3D-printed parts have always had layer lines or roughness,” said Dr. Cora Leibig, Chromatic CEO and founder.

“We have developed a way to easily and cost-effectively 3D print products that are ultra-smooth without additional steps. It’s a breakthrough for 3D printing those professional applications that must be airtight and watertight.”

As well as having great and smooth aesthetics, the system has high accuracy, allowing the printing of consistently thick parts, at the submillimeter scale. This means that the printer and materials are also useful for printing expanding elastomeric parts such as bladders, or even bellows.

The researchers at the company realized that by fine-tuning the viscosity and surface tension of the company’s printable thermoset polyurethane materials, they could create ultra-smooth prints with no stepping. This led to the development of Smooth-mode.

“We developed a way to go beyond simply applying our reaction technology to FDM printing,” said Dr. Bart Engendahl, Chromatic’s managing director in Germany.

“Smooth-Mode uses chemistry to create an ultra-bonded and smooth part. We believe this printing technique delivers the world’s smoothest printing along the Z, or height, axis.”

The company portfolio also includes other thermoset elastomers for applications in transportation, industrial seals and gaskets, textiles, medical devices and defense. Their thermoset elastomers come in a range of Shore A hardness ratings from 50 to 90, as well as custom grades with varying colors, hardnesses and special properties.

Special additives can be added to change the properties from normal elastomers to ones with functional usages such as antibacterial, static discharge, and biocides.

So if your company or project has a need to produce industrial quantities of super-smooth printed rubber gaskets or other seal-type things, then head over to the Chromatic 3D Materials website at this link.