Living organs for medical experimentation are pretty hard to come by, on account of human beings actually using them on a day to day basis. To rectify this, the concept of the organoid has been developed.

Functional Organ Models

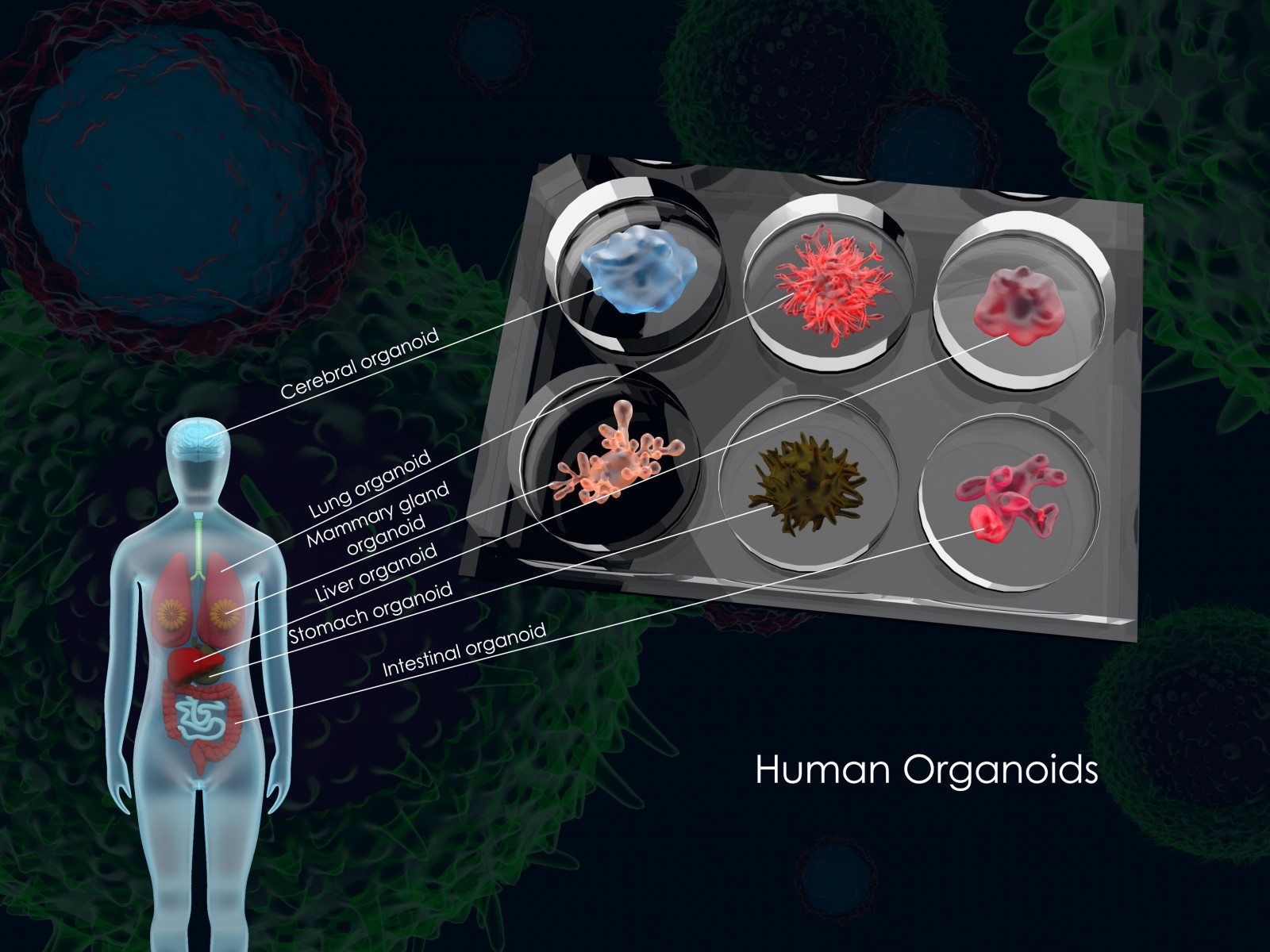

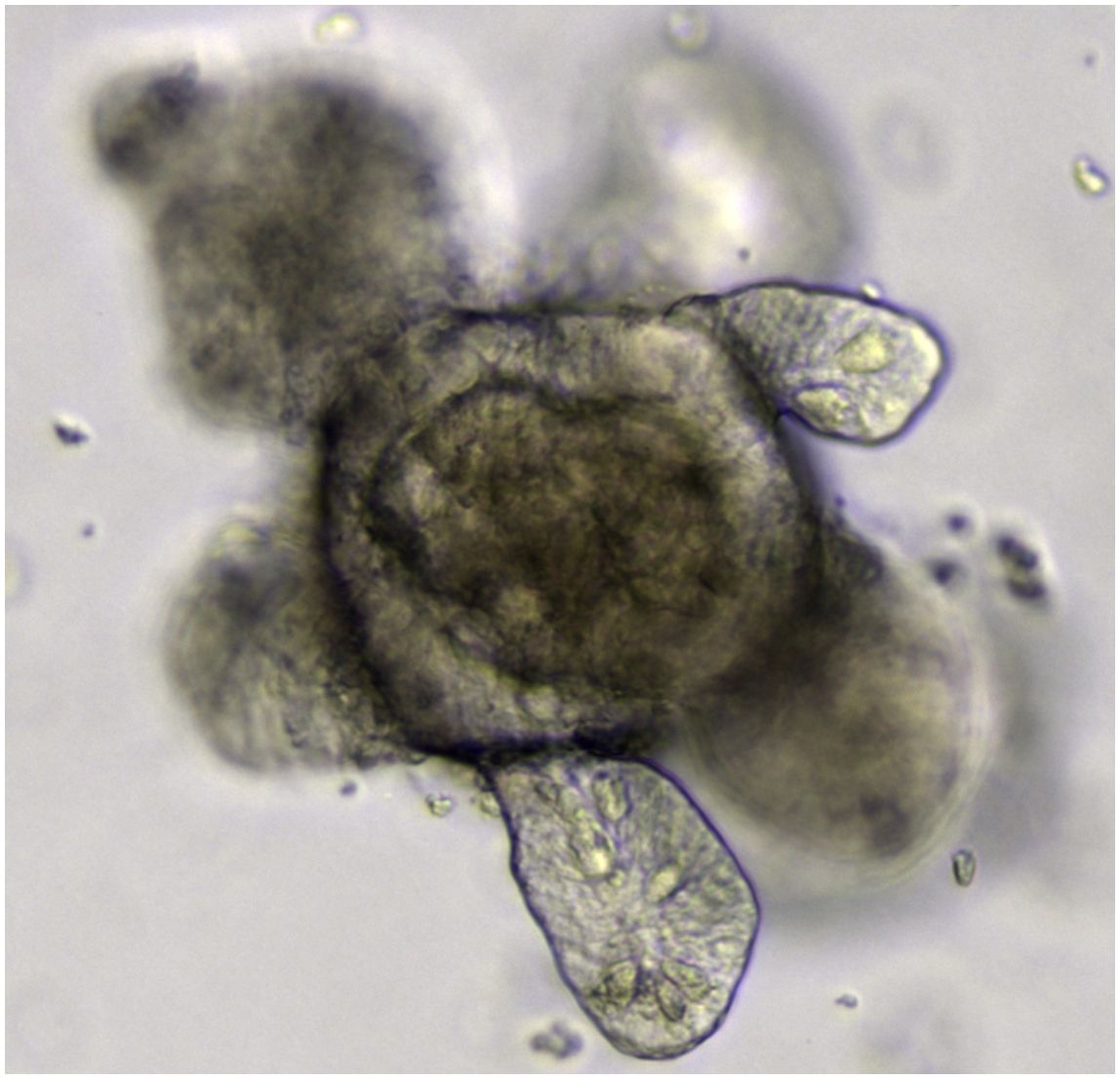

Organoids are mini-versions of organs that replicate various biological functions, and they are grown in-vitro, in a petri dish or test tube or some other kind of container outside of the normal environment of the body.

Manufacturing of organoids has had its limitations however, as it has been difficult to demonstrate consistent and robust extraction of mature organoids from renewable cells.

This could be about to change though, thanks to a team of researchers from the Swanson School of Engineering at the University of Pittsburgh who have been awarded funding to further research into organoid production using AI and 3D printing.

The team of researchers, led by principal investigator Ipsita Banerjee, have been awarded $500,000 by the National Science Foundation to utilize artificial intelligence to accelerate the development of organoids, which has traditionally been heavily based on a trial-and-error approach. The team is multi-disciplinary and comes from various institutes at the University of Pittsburgh, the Allegheny Health Network, and Duquesne University.

New Method

Usually, organoids are created using a chemistry-based experimental approach, but the new method involves mechano-transduction pathways, or the process in which cells respond to mechanical stimuli, to regulate manufacturing while also exploiting cytoskeletal rearrangements that are part of the organoid phenotype.

For those who do not have a background in cellular biology, mechano-transduction is any of various mechanisms by which cells convert mechanical stimulus into electrochemical activity.

In this case, the mechano-transduction will be controlled by bioprinting the organoid phenotype, while machine learning models will identify signature cytoskeletal states associated with the phenotype. The AI will assist with accelerating development and will enhance accuracy in predictions of organoid behavior for further research.

“Our vision is to enable organoid technology to finally realize its potential in clinical research and drug development,” said Banerjee.

“This breakthrough research will benefit society and the healthcare system at large by creating a more efficient, effective and sustainable way to design these structures.”

The printed organoids will be used to conduct complex research on human tissue physiology, genetic diseases, organ-specific infectious diseases and cancer.

Organoids can be used for replicating functions of almost any organ, be it via the production of lung, mammary, liver, stomach, pancreas, and even cerebral organoids.

“Central to our goal of organoid manufacturing is the integration of bioprinting and artificial intelligence to enable automated and non-invasive learning of different types of organoids,” said Banerjee.

“Bioprinting also will enable us to scale up the production of these structures in quantity and quality over time, without the restrictions we currently face using traditional methods.”

The research will provide trainees with multidisciplinary skill sets, encompassing bioprinting, organoid engineering, imaging, and AI methods. The funding has been awarded as part of the National Science Foundation’s Future Manufacturing program.