The range of materials available in 3D printing, even just within Fused Deposition Modeling, has grown considerably in the last few years. Not only are there multiple reputable brands that carry all types of thermoplastics such as ABS, PLA, nylon, and PETG but there are also composites of all those materials that are embedded with various particles/strands like carbon fiber and fiberglass. There’s yet another variety of composite 3D printing that’s becoming increasingly popular: continuous fiber.

Chopped vs Continuous

With standard fiber-filled filament, the fiber strands are chopped very short to make the material printable. The most obvious drawback is that there’s little overlap between the fibers and practicality no fibers that cross adjoining layers. As such, parts printed with fiber-filled materials are often only marginally stronger or stiffer than standard 3D printed parts.

Continuous fiber 3D printing is exactly as it sounds. Rather than embedding millions of half-a-millimeter-long strands of fiber into the filament when it’s manufactured, a spool of fiber is used to embed very long strands of fiber into parts as they are printed. Continuous fiber 3D printing provides substantially more strength and stiffness because it better mimics the manufacturing process of traditional carbon fiber parts where long strands of fiber are layered on top of another in a resin.

The Costs of Conventional Carbon Fiber

Conventional carbon fiber parts are very expensive not because of the cost of the raw materials but because of the costs of the equipment needed to ship and process those materials. Pre-preg is a term that applies to a composite of carbon fiber and resin that’s still wet and ready for shaping; it has to be refrigerated from the moment it’s manufactured up until the point it’s used, meaning there are lots of extra logistical costs. To make carbon fiber parts, molds first have to be made, which of course aren’t free. And curing the final parts requires autoclaves that are as large as the parts themselves, and considering that carbon fiber is a popular choice for building airplanes, the autoclaves are understandably expensive to build and operate.

With continuous fiber 3D printing, nearly all of those costs go away without sacrificing strength. There are several companies that offer continuous fiber 3D printing but we’re going to look at three of the best-known brands.

Markforged has several machines that can lay continuous fibers. Their systems rely on separate toolheads to deposit the different materials: one extrudes a thermoplastic matrix just like a normal 3D printer and the other lays down strands of fiber in select areas to increase tensile strength. They can work with carbon fiber, fiberglass, and kevlar.

Desktop Metal’s Fiber system works much in the same way as the Markforged solution except that its Micro Automated Fiber Placement (µAFP) technology uses rolls of fiber tape rather than spools of fiber. It can embed carbon fiber into nylon, PEEK, and PEKK, and nylon can also be embedded with fiberglass. They claim their parts can be stronger than steel and lighter than aluminum.

https://www.youtube.com/watch?v=n4jSYMIqxHk

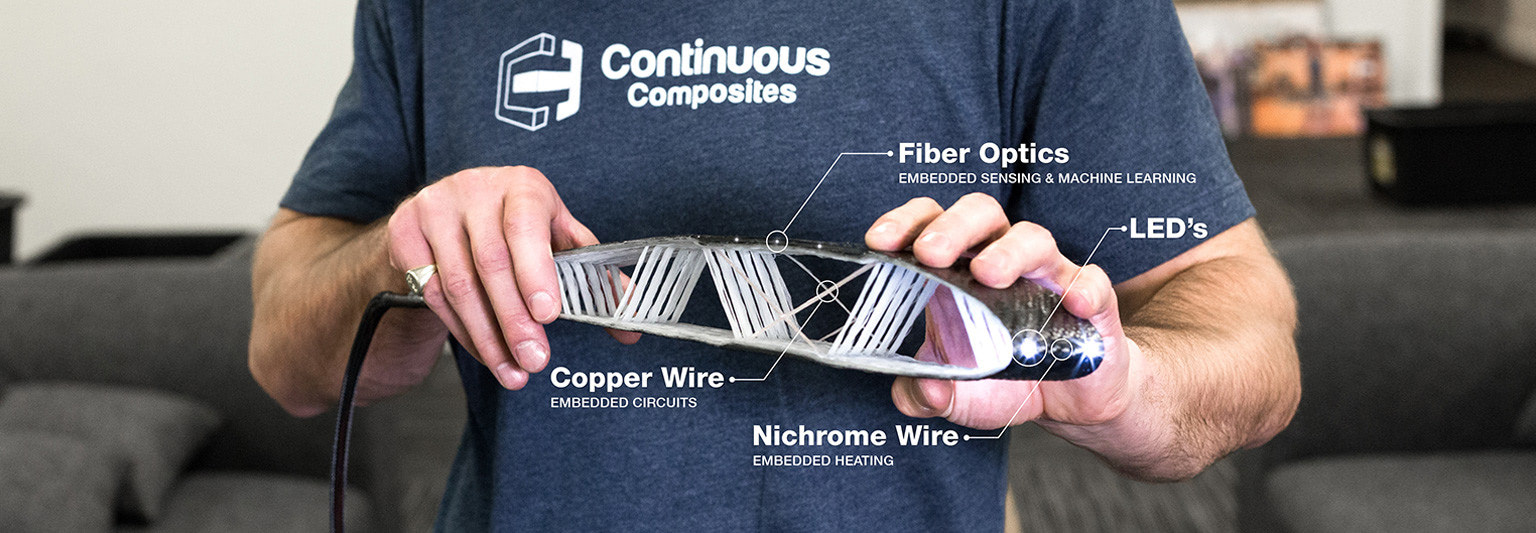

Continuous Composites takes a different approach with their CF3D solution. Instead of using a thermoplastic for its rigid material, it employs a photopolymer. The toolhead coats the strand of fiber with a photopolymer as it’s deposited and then immediately cures it with a powerful UV light. This allows it to embed every single line with fiber, not just select areas. It also means it can bridge long gaps without the need of supports. The CF3D system is compatible with structural fibers like carbon, glass, and aramid as well as functional fibers such as optical and metal, which enables all kinds of nifty tricks like embedded sensors and circuits.

https://www.youtube.com/watch?v=QsiOOYK7J6k

While these systems are not as affordable as most desktop 3D printers, they’re significantly more accessible than most metal 3D printers and conventional carbon fiber manufacturing equipment, and they’re way easier to use. The material selection for this segment will continue to grow with the 3D printing materials sector as a whole; more polymers will be developed for the matrix and more fibers will be released to match. I wouldn’t be surprised if there are already material scientists developing fibers that expand and contract when heated or exposed to an electrical current, which would delight those who are working on soft robotics and embedded electronics.

Featured image courtesy of Continuous Composites.