University of North Texas has just received a couple of Department of Energy (DOE) grants to push forward their ongoing research into 3D printed automotive structures. The first grant covers embedded sensors and the second covers a means for ultrasonic defect-detection in automotive 3D printing.

Sensors

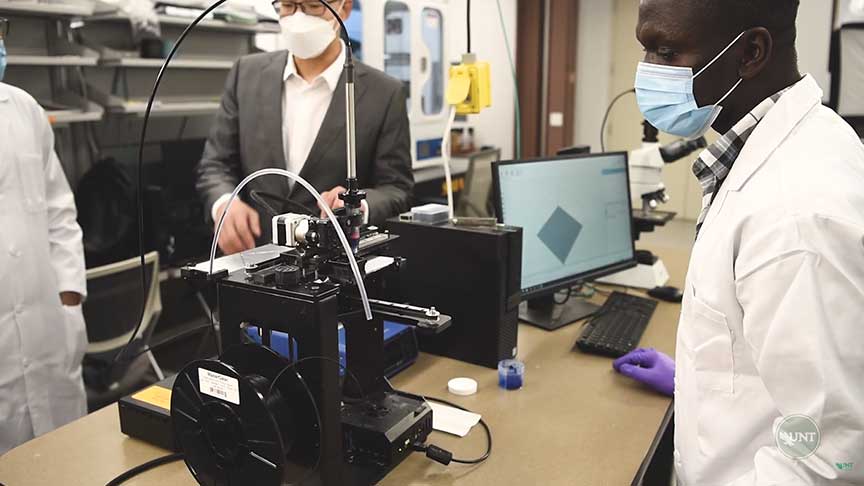

The first grant (1.5 million USD) announced by the university covers 3 years of research and will be conducted at the UNT Center for Agile and Adaptive Additive Manufacturing (CAAAM) with the assistance of DOE scientists from the Center for Nanophase Materials Sciences at Oak Ridge National Laboratory. ORNL have been very proactive in 3D printing lately, especially in the domain of nuclear engineering.

The funding will further development into the fabrication of a lightweight, 3D printed carbon fiber composite material equipped with embedded sensors for use in car structures.

The team will assess various materials which can be embedded with flexible sensors during printing. These sensors will enable real time monitoring of the structures, wherever they may be on the vehicle. The team is looking at using this technology in the main vehicle structure, which they say can be manufactured with additive manufacturing, as well as other structures such as tyres and fuel tanks.

This will, in principle, allow a driver to receive up-to-date information on the health of their tyres or the quantity of fuel remaining in the tank.

“Once we have developed and successfully tested materials, we can provide stronger, safer and more lightweight options for automotive additive manufacturing,” said Yijie Jiang, an assistant professor at UNT’s Department of Mechanical Engineering.

“Readily available, proven materials will provide opportunities to lower costs and advance the industry.”

Ultrasonic Quality Control

The second grant (1 million USD), which was announced by the university this week, covers research into ultrasonic defect-detection of the microstructure of 3D printed automotive components.

“We’re going to use ultrasonic technology to monitor each part in real time and determine if there’s a defect,” said Professor Haifeng Zhang, who is co-principal investigator on the project at the UNT Department of Mechanical Engineering.

“By detecting a possible defect earlier in the process, we could revise the manufacturing parameters sooner, saving time and money.”

The in-situ monitoring of AM part quality during manufacture is a hot topic of research at the moment, and is a fairly critical step in realising a fully Smart Factory, as promised by Industry 4.0.

“Additive manufacturing has potential to revolutionize manufacturing operations and significantly disrupt the conventional handling of new and replacement parts in all industries, including nuclear, which is what much of my research is in,” said Zhang.

The DOE has already been dedicating their supercomputer resources to developing AI-assisted in-situ fault detection for titanium parts, as seen in this article, albeit with X-rays rather than ultrasonic sensors.

Ultrasonic sensors are certainly more accessible than X-ray sources, and systems like this may even find themselves on the factory floor, rather than exclusively in government research facilities.

You can see some examples of the kind of work CAAAM is doing in the video below.