New 3D-Printing Technique Creates Dual-Material Objects from Single Resin

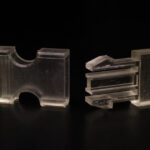

Researchers have developed a new Vat photopolymerization technique that creates both permanent objects and dissolvable supports in a single process. According to a... read more »