With construction 3D printing taking off, it’s no wonder that companies would start inventing improved material solutions for construction issues. Purdue University is taking a new stab at good old cement itself. Purdue researchers have invented a 3D printed cement paste that gets stronger as it cracks. Their bio-inspired design could potentially make construction stronger during wildfires and earthquakes.

The design takes inspiration from the shells of arthropods such as lobsters and beetles. The overall structure interlocks in such a way as to spread damage between the printed layers of a material. This distribution acts like the difference in trying to break a bunch of uncooked spaghetti noodles as opposed to a single noodle.

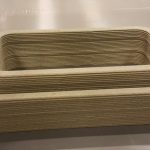

“Nature has to deal with weaknesses to survive, so we are using the ‘built-in’ weaknesses of cement-based materials to increase their toughness,” said Jan Olek, a professor in Purdue’s Lyles School of Civil Engineering. The bio-inspired designs include “honeycomb”, “compliant” and “Bouligand” shapes. They all distribute force differently.

Bio-inspired Design

According to Purdue:

The team is also using micro-CT scans to better understand the behavior of hardened 3D-printed cement-based materials and take advantage of their weak characteristics, such as pore regions found at the “interfaces” between the printed layers, which promote cracking.

We covered their work with CT scans and bio-inspired designs previously. They used the structure of the mantis shrimp and its dactyl club appendage to make stronger forms. The twisting cracks dissipate energy and prevent the club from falling apart and, in fact, make it stronger as it twists.

The designs that the Purdue researchers have introduced allow for different behaviors once the cement hardens. The honey-comb shape is one of the strongest forms in nature, which is why bees use it. The shape distributes force very evenly across all its corners.

The Bouligand architecture, for example, takes advantage of weak interfaces to make a material more crack-resistant, whereas the compliant architecture makes cement-based elements act like a spring, even though they are made of brittle material. The Bouligand architecture, for example, takes advantage of weak interfaces to make a material more crack-resistant, whereas the compliant architecture makes cement-based elements act like a spring, even though they are made of brittle material.

Clearly, the new applications of these can be of great use in various places. This is especially true of earthquake prone regions like Japan, where they modify architecture already. The spring-like elasticity of Bouligand architecture would be very useful there. The concrete would also be useful knowledge for areas where wildfires are very common. It could allow for all sorts of new safer structural forms and shapes.

Featured image and video courtesy of Purdue University.