It’s been a big year for metal printing. Multiple companies popping up all over the place along with new printers left, right and centre. While many companies are rushing to make their mark in different ways, cost is still a core factor in kick-starting the metal printing revolution. Metal prints are not as resource or time-efficient at this point, which drags down their demand. However, the LightSpee3D might just be the next leap in this burgeoning, crucial field adding both new levels of speed and cost-efficiency.

Australian-based Charles Darwin university has acquired access to the LightSpee3D metal 3D printer due to a $400,000 (AUD) govt grant. This will enable the university to do vast amounts of new research using the printer. The university will be looking at different applications for the printer. One of the core areas they will be working with is assisting businesses operating in remote areas. With this printer they may be able to significantly reduce their production costs and supply needs.

“This creates the ability for us to break through some of those previous barriers, maybe around costs or other things. If we can do it cheaply here through things like this creative manufacturing process, the 3D printing process, then suddenly we’re having jobs not just around digging it up but turning it into things” said NT Chief Minister Michael Gunner.

The LightSpee3D

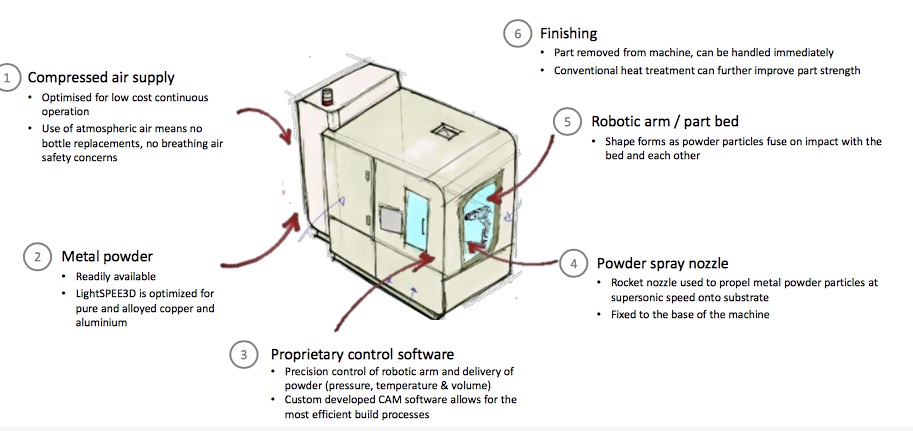

The LightSpee3D has a supersonic print nozzle and 6-axis robot. On top of that, it also has an enclosed build chamber. It employs the use of compressed air to accelerate the particles and build pressure. What’s most impressive is that it reduced production costs from $3,000 to $30, an unbelievable number. Similary, it can reduce production time from 2 to 30 minutes in certain cases. And this is all compounded by the fact that the LightSpee3D is a mass production device.

The company refers to it as a cold-spray 3D printer. This refers to a means of firing particles at a surface to build up a physical object. This method enables the acceleration of particles making it faster. This builds up prints faster than traditional layer-by-layer AM methods. It is based off of an old coating technique but is now being used for manufacturing.

The image below details the steps of the process:

All images gathered from coldsprayteam.com