This is an article written by Simon Duchaine, CMO of Dyze Design.

Dyze Design, a Montreal based company, is really pleased to announce the soon-to-be launched Kickstarter campaign for its new product: the Tungsten Carbide Nozzle, a state of the art durability and performance 3D printer nozzle for almost any popular desktop 3d printer on the market.

What is Tungsten Carbide?

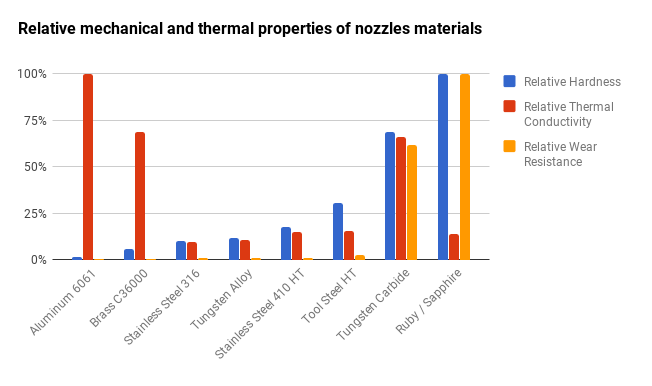

“Tungsten carbide, not to be confused with tungsten alloy (which is metal), is the ceramic of choice when it comes to wear and abrasion resistance. Cutting tools for steel and tool steel are made from tungsten carbide. It is also used extensively in the mining industry as a button insert for crushing rocks.” Says Philippe Carrier, Dyze Design’s Head of R&D. The high thermal performance of the tungsten carbide keeps the nozzle tip hot, thus allowing faster printing speed without sacrificing the quality. In fact, the thermal conductivity ensures that heat is able to travel up to the tip of your nozzle, keeping your molten plastic at the right temperature. Having a bad heat conductor may lead to colder extrusion, thus poor layer bonding and greater flow fluctuation. For these reasons, any kinds of steels and ruby nozzle will lead to lower extrusion flow.

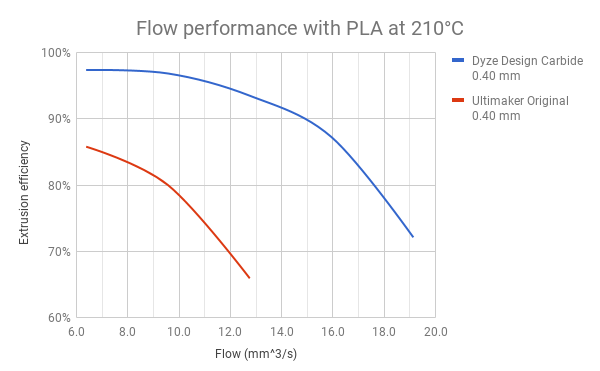

The tungsten carbide nozzle allows for much easier extrusion when comparing to a brass nozzle from for instance Ultimaker. In fact, the output flow can be increased by around 80% while having the same results.

Furthermore, tungsten carbide has exceptional wear resistance due to its high hardness. Both the nozzle hole size and height will hardly show any wear, no matter how long or how hard you use it.

Tungsten Carbide Nozzle Features

- Ultra wear resistant

The high hardness of tungsten carbide will provide a lifetime of carefree extrusion. The unequalled wear resistance will ensure both the nozzle diameter and flat will keep the same dimension, and so will your printed parts. - Low pushing force

The high thermal conductivity of both the nozzle tip and body will pump all the required heat to maintain an even temperature while extruding. Viscosity highly depends on the plastic temperature for a constant shear rate. The flow pressure will be constant resulting in excellent results and stability. The ease of pushing the filament will give an extra margin for your extruder safety. - Faster speed

Due to the high thermal performance of the nozzle in general, the printing speed can be pushed even further without sacrificing the quality. The special shape inside the nozzle allowed by the manufacturing technique improve the flow where the diameter gets reduced, thus allowing faster flow rate. - Low friction

The whole nozzle is nickel plated for enhanced slippery properties. Plastic will slide on the nozzle instead of sticking to it. This result is cleaner parts and less dragging problems. - Any material

From printing PLA to carbon fiber reinforced plastics, this nozzle can handle anything. The low friction coating greatly helps with printing flexible filament, allowing them to slide throughout the nozzle. A single nozzle will offer quality prints, wear resistance and high flow. No need to get a ton of different nozzle when a single one can offer the best of all worlds. - Unbeatable price / performance

Tungsten carbide is easier to produce than corundum (Sapphire, Ruby, etc) and the performance is very similar. The use of copper makes it very easy to manufacture and offer amazing thermal performance. The whole package is a win-win situation in terms of performance and price.

This Kickstarter Campaign goal is to raise $15,000USD. This money will go towards ensuring that the company can validate long-term leaks, measure performance in extrusion, flow and oozing, measure the fatigue of the assembly, make retouches on the different molds, manufacture other nozzle sizes and do high temperature tests.

The campaign is planned to be launched on Kickstarter on March 5th.

To learn more about this upcoming Kickstarter campaign or to subscribe for launch date notifications and access to early birds pledges, click here to visit Dyze Design.