Few materials have produced quite as much buzz as Graphene. It’s easy to see why it’s so popular, after all it is an organic, conductive material that has wide applications in multiple electronics goods. So, producing graphene is clearly a major draw for many companies. A new research project at Rice University in collaboration with Tianjin University might have broken new ground in producing graphene.

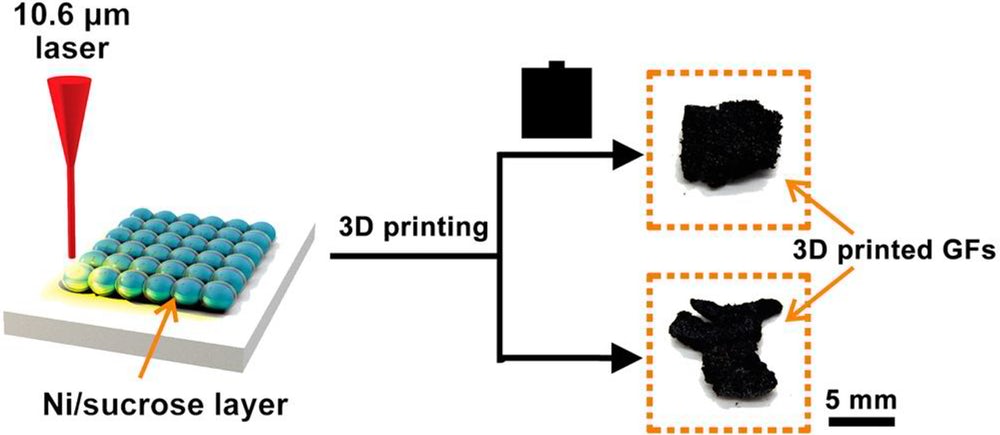

The researchers have come up with a novel new method of processing sugar and nickel into graphene. The study is unique in its approach due to how it uses non-graphene materials to produce graphene. The team used an SLS system to create fingertip sized blocks of graphene foam. As this is an SLS based experiment, it required the use of nickel and sugar in powdered forms.

The method is actually quite simple in comparison with the complexity of most means of producing graphene. The entire process takes place at room temperature and molds are not necessary. The researchers used a commercially available CO2 laser. The experiment also provides the ability to produce various types of graphene foam. Among these various foams are graphene rebar, nitrogen doped and sulphur doped graphene.

Even though the process produces a low density form of graphene that consists of pores as 99% of its volume, it is, nonetheless, a great starting point for future improvements. The research was a collaboration between multiple parties, including Air Force Office of Scientific Research and its Multidisciplinary University Research Initiative, the China Scholarship Council, the State Key Program of National Natural Science of China, the National Natural Science Foundation of China, the Special Foundation for Science and Technology Major Program of Tianjin and Universal Laser Systems.

Graphene Printing

Graphene is a single layer of pure carbon with conductivity and high material strength. While graphene is in heavily demand, scientists have yet to find a way to mass produce it. This study illuminates certain pathways towards that goal.

Previously, this same group of researchers developed graphene rebar. Graphene rebar is a durable material that can retain its original shape under 3,000 times its own weight. However, 3D rebar production is quite complex, requiring extreme temperatures and a pre-fabricated mold. This new method provides a simpler means of producing carbon nanoscale structures.

The production of graphene has often coincided with the 3D printing industry. We’ve covered it before on the bioprinting side of the equation. The bioprinting experiment created bacteria that could metabolise certain organic compounds, leaving behind graphene.

Graphene has applications in batteries, new types of non-metal cables and flexible technology. This gives the material a very high demand. It is immensely versatile, but also expensive to produce. Thus, scientists have been scrambling to find a means of producing it cheaper. Future developments in this line of experimentation may be able to provide that.

All images retrieved from rice University.