We have covered the 3D printing ambitions of Oak Ridge National Laboratory a couple of times before. And they are indeed HUGE ambitions.

Take a look at their 3D printed nuclear thimble gizmo and their 3D printed nuclear reactor here.

But ORNL does not exclusively deal with nuclear power. They still have a hand in developing technologies to enhance fossil fuel power generation processes.

Their most recent 3D printed device does exactly that, and the device in question is designed to capture carbon dioxide from fossil-fuel carbon-emitting smokestacks via a process of chemical absorption.

It works by connecting the exhaust gas flue to an absorption column inside which the 3D printed component is housed. The gas flow is passed through some chemicals (such as monoethanolamine) which react with the gas, capturing the carbon dioxide in the chemical. The problem is, this reaction being exothermic generates a lot of heat in the column, which reduces the efficiency of the reactions. So the new ORNL device serves as a kind of a heat exchanger. It IS a heat exchanger.

The GIF below illustrates the flow of the gas and coolant paths. The coolant inlet is at the right, the gasses are moving down the column from top to bottom, they pass through the 3D printed coolant channels and the removed heat is dumped out of the outlet on the left hand side of the column in the image.

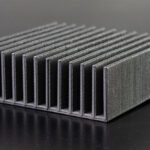

The GIF above shows the cross section of the column. The image below shows the printed device proper, and you can see the inlet port on the side there, for your reference.

The absorption column itself measures at “1-meter-tall by 8-inch-wide”, and before you scold us for mixing metric and imperial, that is a direct quote from the ORNL press release.

You can see the column in the image below. We will assume that the actual column itself is only a fraction of what is shown in the image, unless the engineer installing the component is only 0.75 metres tall (and apparently 8 inches wide).

In the image above the engineer is installing the carbon capture device in between the column’s packing devices. ORNL refers to their 3D printed multifunction heat exchanger as the “intensified device”.

It is multifunction because in addition to the heat exchanger, it also doubles as a mass exchanging contactor.

“We call the device intensified because it enables enhanced mass transfer (the amount of CO2 transferred from a gas to a liquid state) through in-situ cooling,” said Costas Tsouris, project researcher at ORNL.

“Controlling the temperature of absorption is critical to capturing carbon dioxide.”

In addition to the temperature of the reaction, other factors influencing the adsorption of the CO2 are the exhaust gas flow rate, and also the flow rate of the chemical solvent used to react with the CO2.

The experiments so far have determined that there are optimal responses produced by varying these input factors. Next up, the team will attempt to see the effects of varying geometry on cooling and reaction rates, and hope to discover the prime operating conditions for CO2 removal.

In terms of materials, the current device is manufactured from 3D printed aluminium, but researchers are looking at using thermally conductive polymers also.

“The device can also be manufactured using other materials, such as emerging high thermal conductivity polymers and metals. Additive manufacturing methods like 3D printing are often cost-effective over time because it takes less effort and energy to print a part versus traditional manufacturing methods,” said Lonnie Love, manufacturing engineer and designer of the device.

Well, good news Lonnie…

We have an article on thermally conductive 3D printed polymers right here.

ORNL…you are welcome!