You may recall a while back that we did a series of articles on various thermally conductive and electrically conductive polymers suitable for 3D printing.

In this article, we will revisit the concept of thermally conductive plastic filaments, because a team of researchers has released a paper referencing the very materials that we referred to previously.

The researchers from the South-Eastern Finland University of Applied Sciences (XAMK), and the University of Southern Denmark have published their findings around the use of thermally conductive plastics in combination with topology optimization for the production of passive heatsinks.

Specifically the research focused on the use of the ICE9 Rigid Nylon thermally conductive nylon filament from TCPoly, for the design of passive heat sinks using topology optimization for anisotropic heat transfer.

ICE9 Rigid Nylon is one of the filaments we looked at in our previous article on thermally conductive plastics.

Recall how we said that both electrical and thermal conductivity can be altered by the addition of carbon to plastic bulk materials.

The specimens in the research were printed in various orientations and topologies and thermal conductivity measurements were performed to assess the effectivity of the printing process parameters.

The research showed that their experiments showed a 10%–20% reduction in thermal resistance compared to a reference straight fin design.

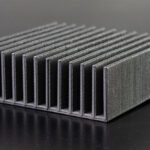

The image below shows a schematic of the aforementioned straight fin design used in the experiments. Reference samples were made from both printed filament and from extruded aluminum.

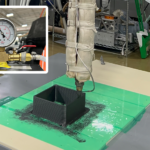

The heatsinks were produced with a Minifactory Ultra 3D printer. The printer was selected due to its ability to print high temperature filaments with (dual) nozzle temperatures of up to 470°C.

Due to the anisotropic differences between orientations (especially regarding air gaps and layer bonding imperfections), it was noted that there was better thermal conductivity in one orientation (in-layer orientation) compared to the cross layer orientation.

This table shows the results of the thermal conductivity experiments for both in-layer and cross-layer orientations of the ICE9 samples compared to the reference designs.

Various optimizations were carried out before the final prints to eliminate air gaps and other defects.

In practice, according to the paper, the reduction in air gaps was achieved by adjusting material fed (flow), the width of the print lines (line width) and the settings for filling and infill overlap. By adjusting these settings, it was possible to achieve the optimal prints with the smallest air gaps.

The paper concludes that topology optimization can indeed achieve improved performance of passive heat sinks produced using thermally conductive filaments such as the ICE9 Rigid Nylon material.

The best designs that the researchers had tested demonstrated a 10% and 20% lower thermal resistance when compared to the reference straight-fin heat sink in the vertical and horizontal installation directions, respectively.

In terms of the gains from topology optimization, the optimized heat sinks achieved a 5 to 10% improvement in the thermal resistance for the vertical installation direction and a 15 to 20% improvement for the horizontal direction.

This was due to the performance of the straight fin reference design, which has superior performance in that orientation thanks to the layout of the fins which are aligned in the direction of gravity.

It was also noted that control of the thermal environment was necessary to ensure best results, as effects such as warping could affect the isotropy of the thermal conductivity.

In short, the research demonstrates the utility of both topology optimization and thermally conductive filament, but notes that the effectivity of the parts could be improved by tweaking the parameters further to fit thermal performance requirements.

You can read the open access paper, titled “Material extrusion additive manufacturing and experimental testing of topology-optimized passive heat sinks using a thermally-conductive plastic filament” over at this link.