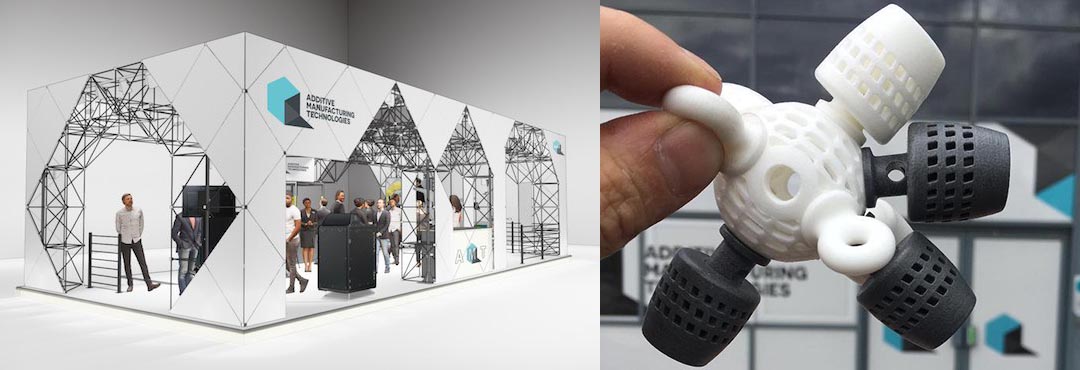

Post-processing specialist Additive Manufacturing Technologies (AMT) has developed a reusable 84 square metre booth that contains over 6,000 3D printed parts. AMT will debut the design at this year’s Formnext as their own exhibition installation.

The laser sintered (PA 2200) connectors bridge together a whopping 1,100 meters of lightweight aluminum tubing. Despite the use of all these components and over a kilometres worth of tubing in total, it manages to weigh only 120 kg. Additionally, the sustainable design can easily be dismantled and reused for other events and exhibitions.

Sustainable 3D Printed Design

Tom Warren, director at Steel Roots Design, responsible for the aluminum tubing commented on this project.

“With around 6,000 3D printed components and over 1km of pole material the structure is a unique feat of engineering, and a great challenge for the Steel Roots Design team. We are delighted with the results and proud that the modular, completely reusable frame material will mean something versatile, lasting and reusable, which moves away from the wasteful tradition of exhibition stand builds.”

A large part of the reusable design comes down to the 3D printed connectors. 3D Printing allows for the production of complex connectors all in one go. Some traditional manufactured connectors can have lead times of multiple weeks or more, requiring a range of different processes. With 3D printing, however, overall manufacturing new batches of such components can come down to a few hours.

The booth will not just host AMT’s technologies but the booth itself will be an example of it. “The whole point of exhibiting at a show like Formnext is to demonstrate your technologies and capabilities,” said Joseph Crabtree, AMT’s CEO.

Previously, companies like Trindo have also experimented with detachable and re-attachable display booths. Their version used inkjet-like sand printing also with connectors that would allow them to easily attach a display and wall behind them. The difference here is the sheer scale and size with which AMT has built the installation. Both cases also showed off the unique designs that only 3D printing can manage.