Stratasys just released news about a new 3D printing system. The H2000 is massive and unconstrained by a build envelope through the use of a horizontal build method with a moving conveyer belt. Stratasys have also stated that it is roughly 10 times as fast as its predecessors.

The company has been hoping to pique the interest of the aviation and automation industries with this new revelation. Seeing as how Boeing and Ford were involved in the project at multiple stages since the beginning, this is likely the case. Aside from building parts for planes, the printer has also found a home in the repair and overhaul industry.

Device Characteristics

While there is no official specs sheet available, we know quite a bit about it from press releases. As mentioned earlier, the the device is roughly 10 times faster than previous entries in Stratasys’ portfolio. It requires an operating space of 33 x 17 ft, with an additional 100 ft needed for supporting equipment. However, the size is dependant on the customer’s demands. Stratasys alters the dimensions and the specifications on a case by case basis.

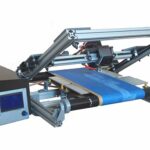

The H2000 is a thermoplastic printer with a robotic arm that lays down every layer horizontally. As a result, the printer works with a horizontally z-plane that allows for parts to be as long as necessary.

The H2000 has 4 bulk material containers on top of the device. These are attached to an automatic hopper refill mechanism. A robotic arm takes on multiple tasks including refilling these containers, ensuring that the H2000 can run unattended. Stratasys developed multiple device parts with longevity and durability in mind. The screws, for example, are capable of lasting for 11,000 hours without replacement. These factors make sure the printer lives up to its “infinite build” moniker.

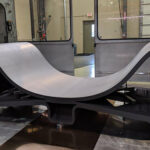

The company also showed off a prototype Interior Closet Door for an aircraft and Aero Fairing Tool. The printer made the closet door in 5 hours and the aero fairing tool in 23 hours at a cost of $8,000, the latter of which usually takes 60 days and $50,000. Airbus have already signed on for printed parts made from ULTEM 9085.

It’s clear that the entire printer was designed with industrial aerospace manufacturing in mind. Aside from the size and scale, the choice of material (ULTEM) evokes the idea of flame resistant parts with a very high strength to weight ratio.

The printer is not on the market yet. The first production models will be shipped out in November 2017 once reliability testing has been completed. According to the Jim Orrock, vice president and product leader at Stratasys, they plan to sell 15 – 20 units in the next 2 years.