In collaboration with Boeing and the US Air Force Research Laboratory (AFRL), Thermwood is printing aircraft demonstrator tools for a low-cost fuselage skin concept. With the use of Thermwood’s LSAM systems, the joint project is producing massive fuselage skin concepts at reduced production and assembly costs. This way of manufacturing also reduces production times from months to weeks or even days.

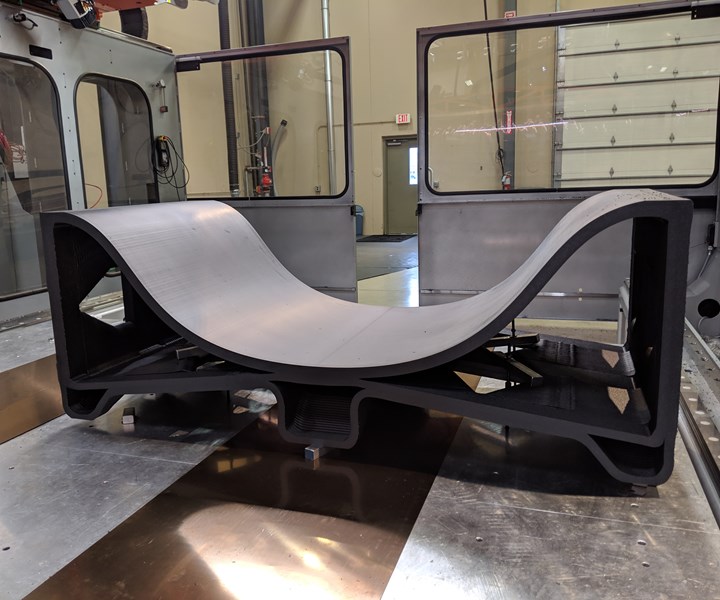

The initial demo tool, measuring 4 feet long, is for an AFRL concept aircraft fuselage skin. The final tool will be over 10 feet long but have similar breadth and weight. The technology lends itself quite naturally to the size one would require for aircraft 3D printing, while providing great speeds and less material wastage than traditional, subtractive methods.

Of the various versions, the initial demo tool required 5 hours, 15 minutes to print, weighing 367 lbs. Afterwards, the tool required some final touches in the form of probing the surface profile and testing for vacuum integrity. For Boeing and the AFRL, the initial tool served as a means of validating the VLP process for high-temperature autoclave-capable materials, using the same bead path as the final print but with a smaller length. The tool passed its room temperature vacuum tests and achieved dimensional surface profile tolerances with flying colors. The final large scale tool will weigh approximately 1400 pounds and require 18 hours to print.

AFRL’s Low-Cost Attritable Technology (LCAAT) program researches different tooling approaches with new technology. The program operates with the goal of breaking the cost growth curve and fielding new systems faster. “We are interested in additively manufactured tooling’s ability to reduce the cost and time to procure autoclave capable tooling,” says Andrea Helbach, AFRL program manager. “Additionally, AM tooling supports changes in vehicle design with minimal non-recurring expenses.”

LSAM Printing For Aircraft

Thermwood’s printed the first version on their LSAM machine at its southern Indiana facility, utlizing a 40-millimeter print core running 25% carbon fiber-reinforced polyethersulfone (PESU). The program is moving further towards producing a full size tool, with Boeing and the Air Force are documenting the operational parameters of the project to transition the technology into production.

“Future fielded low cost, but capable UAV’s will need a responsive materials and manufacturing processes strategy” says Craig Neslen, LCAAT Initiative Manufacturing Lead. “Additive manufactured composite tooling is one of many technologies being evaluated to ensure the industrial base can handle future manufacturing surge requirements as well as accommodate periodic system tech refresh activities which could necessitate minor vehicle design changes at an acceptable cost.”

With this project, Thermwood will be pressing further with their LSAM printers. The company has applied for 19 separate patents on various aspects of this system, with several already granted. This isn’t the first time Boeing and Thermwood have collaborated on printing aircraft tools and components. The companies previously worked on the Boeing 777X program, printing R&D tools. From the looks of it, the joint project is turning out to be a fruitful, on-going partnership.

Featured image and video courtesy of Thermwood.