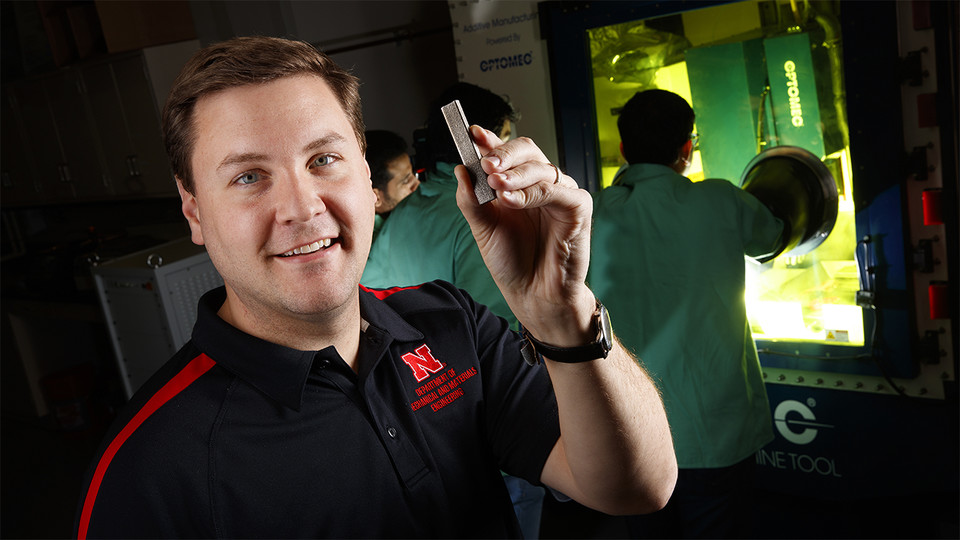

Professor Michael Sealy from the University of Nebraska-Lincoln has invented medical implants that forego the entire process of retrieval after healing. These dissolvable medical implants may alleviate the burdensome removal procedures and limit painful procedures for patients.

The professor underwent his own painful experience with a fractured elbow when he was in fifth grade. While it recovered just fine, the screws caused him immense discomfort. Now, as a professor of mechanical engineering, he’s taken it upon himself to produce a far more efficient magnesium screw implant that dissipates into the body over time, eliminating that painful second procedure meant for implant removal.

“Let’s avoid this whole idea of a permanent implant where you may need a secondary repair revision surgery. Let’s have one that the surgeon puts in and then slowly over time, it dissolves away,” said Sealy.

3D Printing Dissolvable Screws

Sealey built the new screws using an OPTOMEC LENS system, creating the implants from magnesium, which is an essential mineral that helps maintain the structural integrity of bones. However, magnesium also degrades quickly when exposed to oxygen, water and salts, which are abundant in the body.

“We use a laser and it creates very, very small dents, about the diameter of your hair. Putting these dents all into the surface of the implant you are making it harder, you are making it stronger, and you can use that to control how fast these orthopedic implants degrade inside your body,” said Sealy.

The most exciting prospect of these implants is how medical experts will be able to tweak their degradation times. This will allow them to tweak, not just the size and shape, but the dissolution rate for each individual patient. Many modern applications like this are providing the medical community with customisable solutions that suit the individual case, rather than serve a mass production size and purpose. Novel ideas such as these will make treatment safer and more efficient for years to come.

Featured image courtesy of KLNTV, retrieved via their website.