While there are many methods of quality assurance and print testing, some can be more intrusive than others. That’s where non-destructive analysis and quality assurance methods come in. Particularly as it pertains to internal structures, it’s difficult to know what you’ve got during the process. However, there appears to be a growing preference among industrial manufacturers for X-Ray and CT scanning as ideal non-destructive methods for making sure that parts have taken up an intended design.

As a paper published by Nikon Metrology highlights:

“Today, X-ray technologies are increasingly being used in the quality control industry for nondestructive analysis and 3D imaging in other industries such as aerospace, automotive, electronics (e.g., packaging and assembly of printed circuit boards), medical devices, plastic components, and 3D printing (i.e., additive manufacturing). Some of the X-ray based techniques that can be used for NDT include radiography, laminography, computed tomography, limited angle tomography, and computed laminography; they can be of assistance with the determination of voids/porosity, flaws, cracks, inclusions, and the performance of geometric dimensioning and tolerancing of manufactured parts.”

The firm Research and Market also note this increase in industrial usage of X-ray analyses. They expect the market to reach US$722.4 million by 2024. The market is also utilising various X-ray and CT techniques, some of them 2D and others 3D. Each of these methods provide different levels of data and are appropriate for different technologies.

Advantages of CT & X-Ray Print Testing

While certain companies have been using X-rays to examine metal prints for some time, the practice is really taking off. As mentioned previously, there are multiple types of scanning on the market. These include 2D radiography and CT scanning, as well as sub-processes within these labels. X-ray technologies can provide validation for parts, identification of design issues and flaws.

While 2D radiography methods provide limited scans, they can be great for PCBs and other flatter devices. The process can also arrange multiple 2D images into a 3D one, using 2D radiographs at multiple angles. Inspectors can pair these with laminography and 3D model creation. Another application of X-ray and CT has been in the inspection of particles and pellets, before the printing even starts.

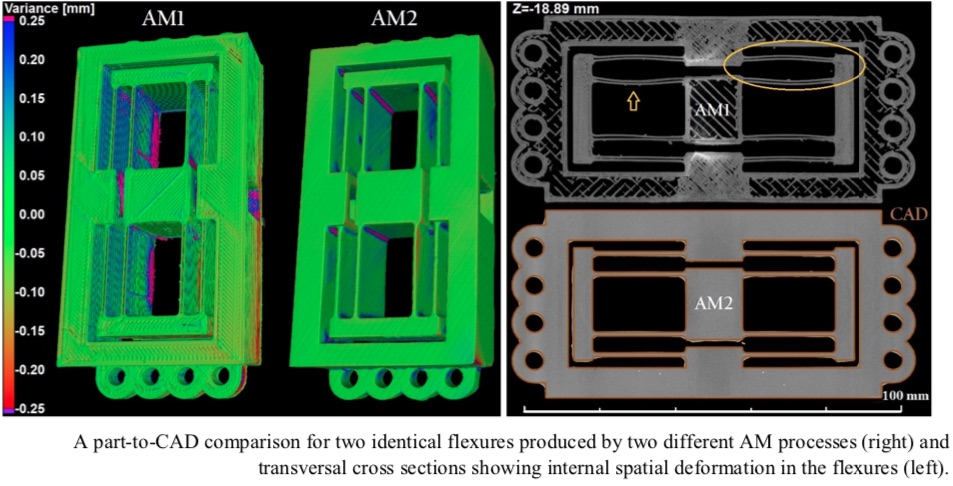

In terms of 3D images, CT scanning can provide a lot of in-depth images and quality assurance guides. Dimensional measurements from CTs account for size and form, wall thickness analysis and part-to-model or part-to-part comparison against a standard. It also allows for defect volume analysis, which can determine voids/porosity, flaws and cracks. As a method, CT scanning provides an in-depth look into the internal structures of printed parts.

Featured Image Courtesy of University of North Carolina at Charlotte.