There are lots of 3D printing videos on Youtube. Some of the Youtubers take their research very seriously and therefore run rather scientifically-rigorous experiments. They’ve created countless hours of videos dedicated to testing different print settings to determine how to get the strongest parts. Oh, you don’t have countless hours to spend sorting and watching dozens of videos on Youtube? Not to worry my time-pressed friend, we’ve done that for you.

Slice Settings for Strength

Note: All of these settings are based on a 0.4mm nozzle diameter; ideal layer heights and widths are ratios of nozzle diameter so you’ll need to adjust your numbers based on the size of your nozzle.

Basic Settings

In this video from Maker’s Muse, the basics of getting stronger prints are covered. There are several slice settings that can be changed for strength, including infill percentage, surface thickness, layer height, and extrusion width. But one setting that often gets overlooked is infill overlap, which affects how well the perimeters are bonded to the infill; usually, only a small increase is needed. These are all great recommendations but they aren’t tested, so let’s have a look at some experiments.

Disable or Reduce Cooling

Not all materials can be printed with cooling but it’s a very useful feature for those that can, such as PLA. Cooling is great for increasing surface quality, especially for parts with overhangs, but it turns out that it’s detrimental to part strength. Good layer adhesion requires that the printing layer and the previous layer fully melt together and that’s harder to achieve when every layer is being actively cooled. If a part’s geometry allows for zero cooling, then turn the fan off to attain the best level of adhesion between layers. If cooling is necessary, set it to the lowest power possible that still results in the desired surface quality. The video below from CNC Kitchen contains PLA and PETG strength tests for when cooling is decreased.

Increase Extrusion Width

Higher extrusion width increases strength up until 150% – 200% of the nozzle diameter. Adjusting this setting increases the flow rate to achieve the desired width, which results in two things:

- More material being deposited per pass.

- More downward extrusion pressure to help the printing layer bond with the previous layer.

As the video below from CNC Kitchen indicates, increasing extrusion width makes parts stronger while using less material and taking less time to print. That’s three upgrades with a single parameter adjustment.

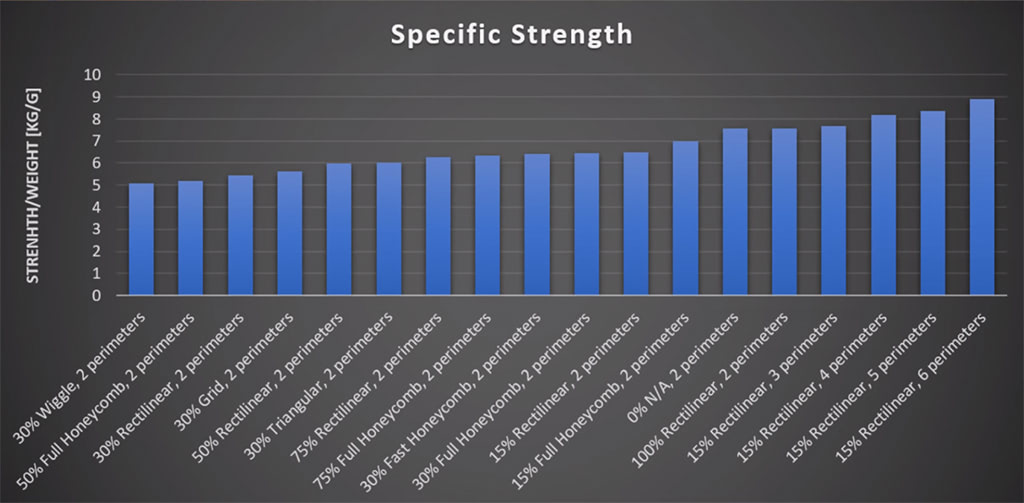

Use Rectilinear Infill and Increase the Number of Perimeters

For parts printed with less than 50% infill, the honeycomb pattern is a bit stronger than most other patterns. However, when printing more dense parts with over 50% infill, rectilinear patterns achieve more strength while taking much less time to print than do honeycomb patterns.

I love this chart because it settles a long-standing debate among 3D printing enthusiasts: what has a greater impact on part strength, infill density or number of perimeters?

CNC Kitchen printed and tested dozens of hooks to create this one chart but the answer is clear: perimeters. Increasing the number of perimeters has a greater impact on strength than does increasing infill density. This is because parts will always experience more strain on the outside than on the inside, making thicker walls more useful than higher internal density. Printing with 100% infill will always achieve the highest absolute strength but getting the highest specific strength, which is a strength-to-weight ratio, requires reducing infill and using more perimeters.

Use Thinner Layers

Thinner layers lead to improved layer adhesion and denser parts (likely) because the rounder shape of thicker layers presents more gaps where adjacent layers meet. It’s also possible that the heat from the nozzle being closer to the previous layer helps the layers bond together better. Either way, going as low as 0.1mm (100 microns) will maximize strength, though the strength dropoff associated with going to 0.2mm (200 microns) is minimal so it’s a worthwhile tradeoff to cut print time by 25%. Recall that the first video recommended using thicker layers for more strength, so why the disagreement? Well, the first video didn’t run any tests so that’s important to note, but the disagreement relates to making other slicing changes when increasing layer height, such as also increasing print temperature and the extrusion multiplier to accommodate that thicker stream of plastic that’s being deposited. In short, some believe that CNC Kitchen’s thicker-layer prints were under-extruded and that that’s why they’re weaker. Knowing whether that’s true or not will require more testing.

Recap

To improve the strength of FDM 3D prints: reduce cooling, increase extrusion width, use rectilinear infill, increase the number of perimeters, and use thinner layers. By implementing these tips and tricks, you’ll be on your way to significantly stronger 3D prints. Just remember to say a silent ‘thank you’ to the Youtubers who have poured heir blood, sweat, and tears into these experiments for our benefit.

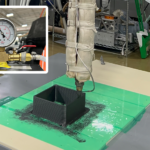

Featured image courtesy of CNC Kitchen.