Metal AM is great, but it’s still a long way off from producing true net-shape parts. To achieve the usable component, smoothed, squared and ready to go, manufacturers often have to post-process the metal printed component so that it is up to spec.

This inevitable adds time and money to the AM process, and somewhat negates the promise of infinite complexity promised by AM advocates. When transferring from an AM process to a non-AM post-process, many things are needed including jigs, fixtures and accurate metrology.

It seems that further down the line, the most efficient manufacturing processes which can deliver on geometric complexity plus high quality finishes and post processes may lay somewhere between additive and subtractive manufacturing (hybrid manufacturing), but with a higher level of automation, particularly at the intersections of where these processes meet.

Hybrid Manufacturing

We have briefly looked at LASIMM before at this previous article from 2019.

Recently, Autodesk has released a video about their (and other company’s) involvement in the project, and provided some insight into how the project has been progressing, and have discussed some project milestones as well as future research questions.

As a reminder, LASIMM stands for Large Additive Subtractive Integrated Modular Machine and is is a collaborative effort including Autodesk, Foster + Partners, BAE Systems,

Global Robots Ltd, Cranfield University and other big hitting names in innovation.

The project is the largest hybrid system of its kind, and it aims to be able to manufacture complex parts in aluminium or steel up to 6 metres in length. In addition to the different hardware requirements, the project is focused on the development of software that can handle the different phases of production from start to finish, and every transfer stage in between manufacturing stations in the total process.

The system is designed to be scalable according to business needs, and offers the option for parallel manufacturing, with the custom software managing the individual hardware subassemblies in a highly optimised self contained fully autonomous production line.

The above image from the video shows the capability of LASIMM, as the part progresses from near-net shape part to full net shape part.

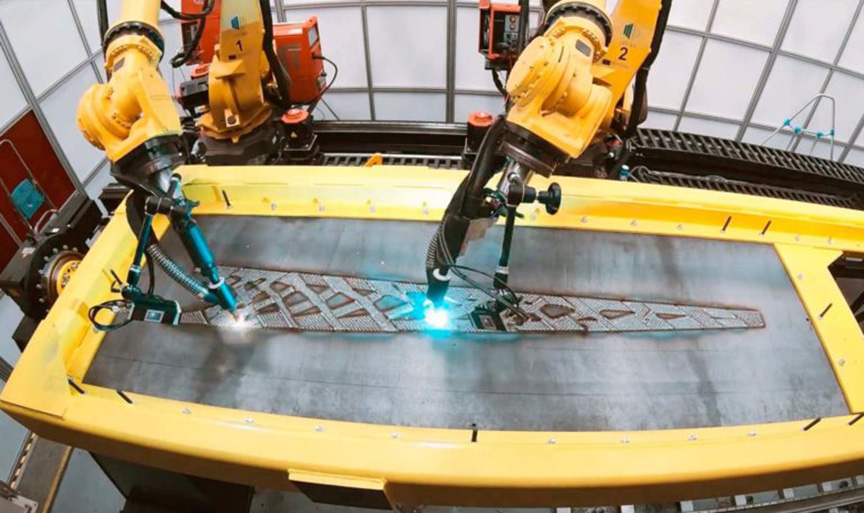

The image below from LASIMM website shows the first stage of manufacture, where the part is printed in the horizontal plane.

The part is not moved from the bed, which would normally cause all kinds of issues in terms of maintaining coordinates of the part. Instead, the entire bed is rotated 90 degrees so the CNC milling system can finish the detailed work.

Conclusions

From the video, the presentation raises some points about the lessons thus learned, and also potential pathways forward in future research.

Firstly, they mention that the software for driving the software for LASIMM has been successfully demonstrated, as has the capability for dual robot additive functionality (2 independent print heads). They have demonstrated this with several large test items.

They note that a higher degree of free form design will be possible with a smaller bed, but that this extra spatial freedom may come with new considerations.

Also, they mention that as steel is a low value material, the cost of using LASIMM for steel part production must be justified by producing high value parts that could not be produced traditionally. Where is the value coming from?

This is an important question to ask especially when dealing with additive manufacturing. Just because it’s cool and awesome, it doesn’t make it economically the right choice.

The final point worth mentioning is a point that I have been asking in my own research in my university day job.

The milling of parts is time consuming and energy intensive, and the LASIMM people note that it should be minimized as much as possible. This can be done with selective milling, and by making tradeoffs also with aesthetics. No need to mill a face if it’s not going to mate with anything. And this spurs the final question: in terms of surface roughness, how smooth is smooth enough?

Food for thought indeed.