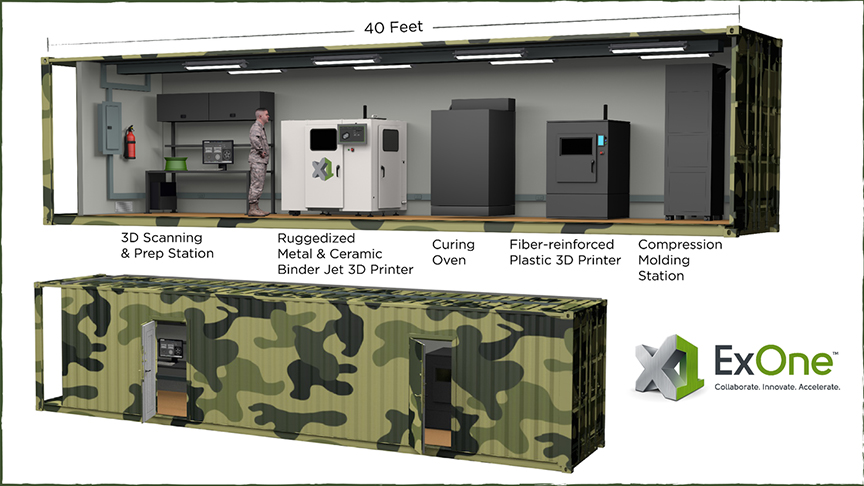

The US military is no stranger to 3D printing, what with their commissioning the largest metal printer and testing conductive plastic 3D printed antenna. A recent contract from the DoD (Department of Defense) is no surprise and fits nicely in the trend of adopting AM across the military branches. And speaking of fitting nicely, the $1.6 million contract went to ExOne to develop and build a metal 3D printing factory that can fit inside a shipping container. That’s a tight fit.

The challenge for ExOne won’t be the metal 3D printing as their binder jet printers produce incredibly complex geometries with mechanical properties that rival machined parts. The trick will be fitting the printer and all the necessary hardware that makes it productive into 320 square feet, and making it sturdy enough to still function after being deployed on the frontline via helicopter. Metal 3D printers have sensitive sensors in order to achieve high resolution, so making them tough enough to maintain that precision after being aggressively moved around is no small order. On top of all of that, the factory has to be easy to use because the troops who will be relying on it won’t specifically be manufacturing specialists.

ExOne CEO John Hartner explains, “We’ve ruggedized the products that are going inside. There’s an element of software that makes the whole thing easier to use together. You start with scanning… so there’s a possibility that you print from a cloud-based repository, but that may not be available for whatever reason, so you may have a broken part that you can scan and do some digital repair to the file and print.” Beyond the metal and ceramic printer, there will also be the curing oven that fully sinters the printed parts, a 3D scanning station for rapid repairs, a fiber-reinforced plastic 3D printer, and a compression molding station.

The whole idea is that soldiers, with only minimal training, will be able to repair a variety of equipment with the factory, from vehicles and machinery to armor and weaponry. Even something as simple as an equipment hook that adds more carrying capacity (or comfort) to a soldier’s backpack could be quickly fabricated at a low unit cost with a container factory, a part seemingly so unimportant that it normally wouldn’t be worth going through the arduous bureaucratic process to requisition from supply HQ. “Sometimes people talk about disrupting the supply chain and getting decentralized manufacturing. This is decentralized and forward deployed, if you will, be it an emergency, humanitarian mission, or frontlines for a war fighter,” said Hartner.