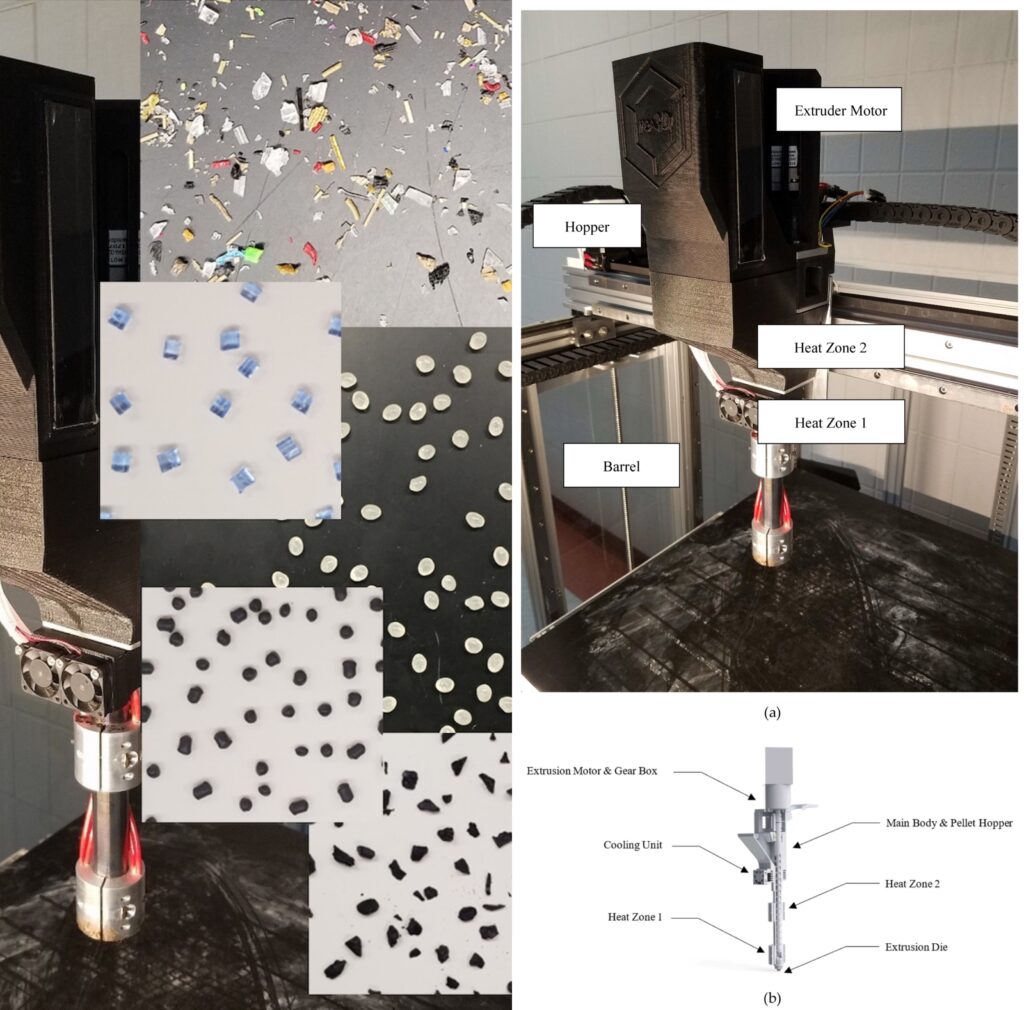

A study out of Michigan Technological University analyzed the economic efficiency of 3D printing various sporting goods using a 3D printer with a pellet extrusion system. This technology also known as Fused Granular Fabrication (FGF) has potential for increasing the use of recycled polymers in 3D printing.

3D Printing Versus Store Prices

While even standard desktop 3D printers boast an impressive return on investment (ROI), the Michigan Tech Open Sustainability Technology (MOST) Lab wanted to investigate the ROI of a 3D printer designed for industrial materials. For the experiment, they compared the costs of printing a skateboard, a kayak paddle, and snowshoes in both virgin and recycled materials against the costs of commercially available versions of the products.

Joshua Pearce, Professor of Materials Science and Engineering at MTU, commented on the printer and the study: “This isn’t a gadget to make toys for your kids; this is an industrial machine meant to make real, large, high-performance products.”

Investment-Worthy ROI

The findings are noteworthy if not unsurprising to 3D printing enthusiasts: the printed versions of the goods were cheaper than the most affordable off-the-shelf versions, even using virgin plastic pellets. The recycled plastic prints were even cheaper. A cost analysis indicated that the machine would be profitable if it printed one of the objects only once per week and could generate millions in profits by printing one a day.

“Once the capital costs are taken care of, which can often be less than a year, FPF or FGF machines have an enormous potential to make profit. Economically, they absolutely make sense.” said Pearce.

Up until recently, affordable 3D printers have struggled to fabricate industrial-grade parts, but pellet extrusion 3D printers that can handle PET (polyethylene terephthalate) and PP (polypropylene) are becoming more accessible. Using these 3D printers, makerspaces and individuals could partner with local recycling centers to reuse much of the waste they collect, printing outdoor furniture and equipment for parks and other public spaces.