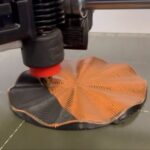

4D printing refers to types of materials that can alter their physical shape in reaction to stimuli after manufacturing. This is due to the use of various materials, depending on the desired affect. As part of a new project, researchers have unveiled objects printed from shape memory polymers that react to heat.

Georgia Tech, Singapore University of Technology and Design and Xi’an Jiaotong University have contributed to the project. Initially, the polymers are printed onto a flatter shape. When the print is heated, it takes its intended, final shape. Researchers use computer simulations to determine what shape the final product will take.

“This new approach significantly simplifies and increases the potential of 4D printing by incorporating the mechanical programming post-processing step directly into the 3D printing process” said Jerry Qi from Georgia Tech.

The application of heat gives a new, permanent shape to the prints. Previously, models were reliant on hydrogels. However, these polymers change shape far quicker than previous prints. Most prints, depending on shape and size, fully form in about 5 seconds.

Potential Applications

While this type of material is fairly new, future iterations could be used to create various compact products. Packaging materials made out of this sort of polymer could be far lass space consuming. If manufacturers can alter the stiffness of the polymer, companies could make furniture that could be shipped in a compact form and then heated to expand into its intended shape.

This could revolutionise storage and shipping because objects made from this polymer can be stacked or stored with ease. Furthermore, this opens the door to building polymers that are reactive to stimuli other than temperature. Future types could potentially react to moisture, sound or force. These could all have potential uses in different situations that require such materials.